149149

Three

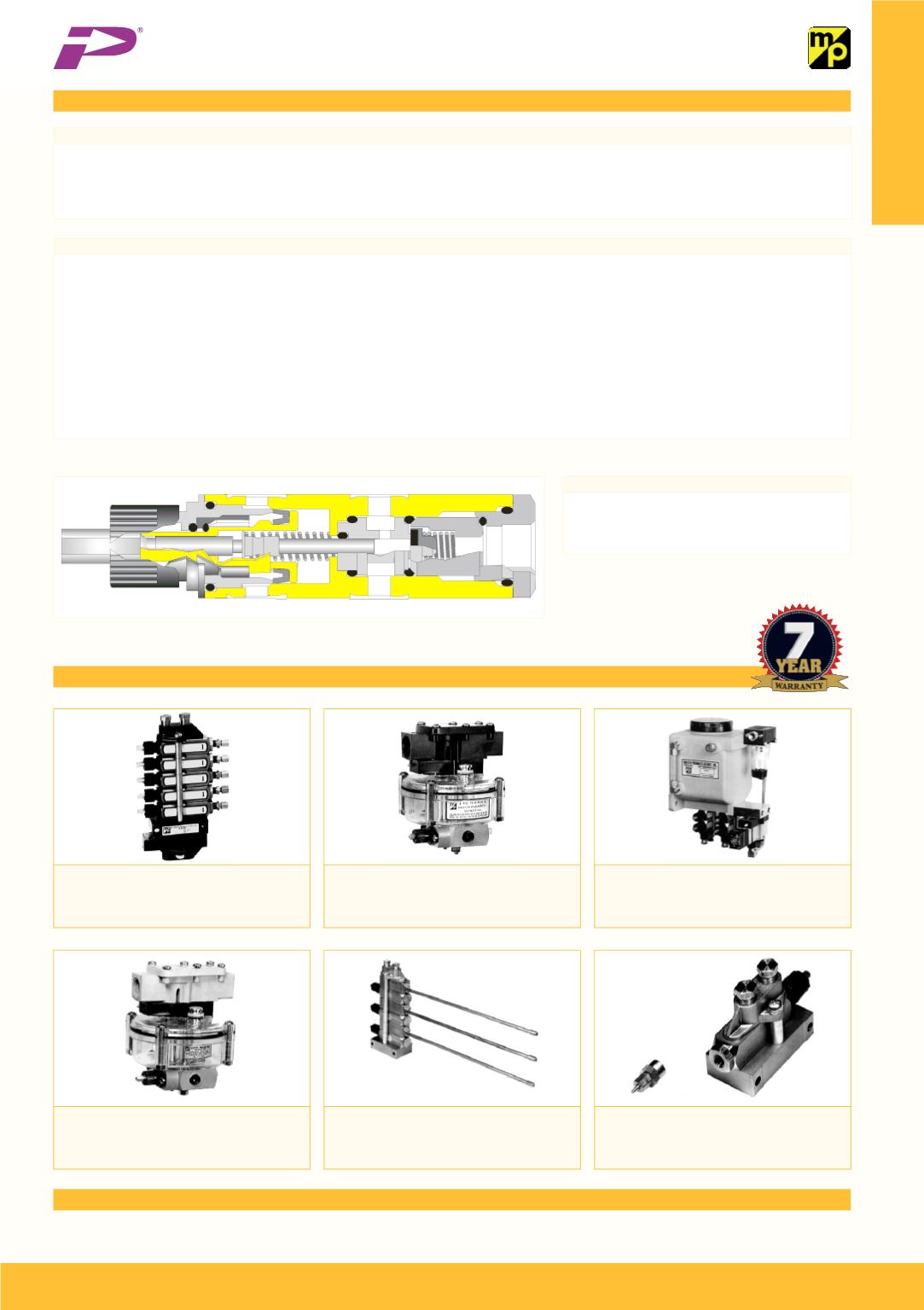

MULTIPLE POINT LUBRICATOR

An assembly of Servo-Meters to provide

lubrication at many different points.

DOWNSTREAM SINGLE POINT LUBRICATOR

Provides lubrication for a single cylinder, air motor

etc. Not for use with air tools.

AUTOMATION PAC.

Self-contained lubrication system, using up to 20

Servo-Meters for 20 lubrication points.

SINGLE POINT LUBRICATOR FOR AIR TOOLS

Specifically designed for air tools, but not other

pneumatic components.

JETMASTER LIQUID DISPENSER

Servo-Meter actuated dispenser propels a

conical air-liquid jet up to 10 inches with pinpoint

accuracy.

LIQUID-ONLY INJECTOR

Servo-Meter actuated dispenser sprays air-free

liquid up to 10 inches. Ejector connected to

nozzle by tubing.

SERV-OIL

THE SERV-OIL

®

INJECTION LUBRICATION SYSTEM

SERV-OIL

®

LUBRICATES THE COMPONENT, NOT THE AREA

SERV-OIL is the most advanced system for the precision lubrication of pneumatic equipment systems, which is used to provide lubrication to all kinds of

pneumatic equipment, fixtures, bearings, slides and ways. It overcomes the control problems encountered with conventional mist lubricators. It also ensures

proper lubrication of pneumatic components in complex circuits and delivers lubricant to points at long distances from the lubricator.

Positive-displacement oil injectors (Servo-Meters) are the heart of SERV-OIL equipment. They put precise amounts of oil right at the points where lubrication is

needed. With SERV-OIL, the amount of oil used is greatly reduced and lubrication is more effective because of the accuracy with which the oil is delivered.

DO YOU NEED SERV-OIL?

If any ONE of the following statements describes a situation in your plant, you could reap long-term dividends with the use of Serv-Oil products from Master

Pneumatic;

• We repair air tools because the vanes are worn and the cylinders and rotors are scored due to insufficient lubrication.

• The appearance of fog or mist lubrication is a hazard in our plant.

• Over lubrication costs us money because of the stringent requirements for disposing of used lubricants.

• Air cylinders in our plant become sluggish because of varnish or other contaminants.

• Torque control in our air tools is variable and doesn’t meet our requirements.

• We set pressure regulators higher than the work requires just to overcome stiction in valves, cylinders or other air components.

• If one pump fails in our lubrication system, the performance of other pumps is adversely affected.

• Sometimes lubricators are turned off; unauthorised personnel are tampering with the lubrication adjustments so that control of the lubrication is not in the

proper hands.

• We use flood coolants to lubricate taps and drills, the cost and environmental impact of this have not been considered.

• It would be to our advantage to know exactly what lubrication is being provided and when to fill our lubrication reservoirs.

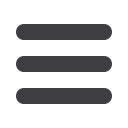

THE SERVO-METER

Heart of the SERV-OIL family of products. It is a

precision, positive-displacement oil injector for use in

several SERV-OIL assemblies for different industrial

lubrication applications.

THE SERV-OIL

®

PRODUCT RANGE

FOR MORE DETAILS AND PRICES PLEASE CONTACT YOUR DISTRIBUTOR