656

Thirteen

TEE

TUBE TO TUBE

PART NUMBER

TUBE OD

PRICE

A9200-04

4 mm

£3.59

A9200-06

6 mm

£3.90

A9200-08

8 mm

£4.61

A9200-10

10 mm

£7.61

A9200-12

12 mm

£9.86

A9200-14

14 mm

£15.62

A9200-15

15 mm

£15.35

A9200-16

16 mm

£18.94

A9200-18

18 mm

£23.04

OFF SET LEG TEE

BSPT MALE

PART NUMBER TUBE OD

THREAD

PRICE

A9230-0418

4 mm

1/8” BSPT

£2.89

A9230-0618

6 mm

1/8” BSPT

£3.05

A9230-0614

6 mm

1/4” BSPT

£3.30

A9230-0818

8 mm

1/8” BSPT

£3.63

A9230-0814

8 mm

1/4” BSPT

£3.67

A9230-0838

8 mm

3/8” BSPT

£4.51

A9230-1014

10 mm

1/4” BSPT

£6.07

A9230-1038

10 mm

3/8” BSPT

£6.09

A9230-1238

12 mm

3/8” BSPT

£8.04

A9230-1212

12 mm

1/2” BSPT

£8.04

A9230-1412

14 mm

1/2” BSPT

£12.40

A9230-1512

15 mm

1/2” BSPT

£12.40

A9230-1612

16 mm

1/2” BSPT

£15.56

A9230-1812

18 mm

1/2” BSPT

£18.96

CENTRE LEG TEE

BSPT MALE

PART NUMBER TUBE OD

THREAD

PRICE

A9220-0418

4 mm

1/8” BSPT

£2.89

A9220-0618

6 mm

1/8” BSPT

£3.05

A9220-0614

6 mm

1/4” BSPT

£3.30

A9220-0818

8 mm

1/8” BSPT

£3.63

A9220-0814

8 mm

1/4” BSPT

£3.67

A9220-0838

8 mm

3/8” BSPT

£4.51

A9220-1014

10 mm

1/4” BSPT

£6.07

A9220-1038

10 mm

3/8” BSPT

£6.89

A9220-1238

12 mm

3/8” BSPT

£8.04

A9220-1212

12 mm

1/2” BSPT

£8.04

A9220-1412

14 mm

1/2” BSPT

£12.40

A9220-1512

15 mm

1/2” BSPT

£12.40

A9220-1612

16 mm

1/2” BSPT

£14.82

A9220-1812

18 mm

1/2” BSPT

£18.96

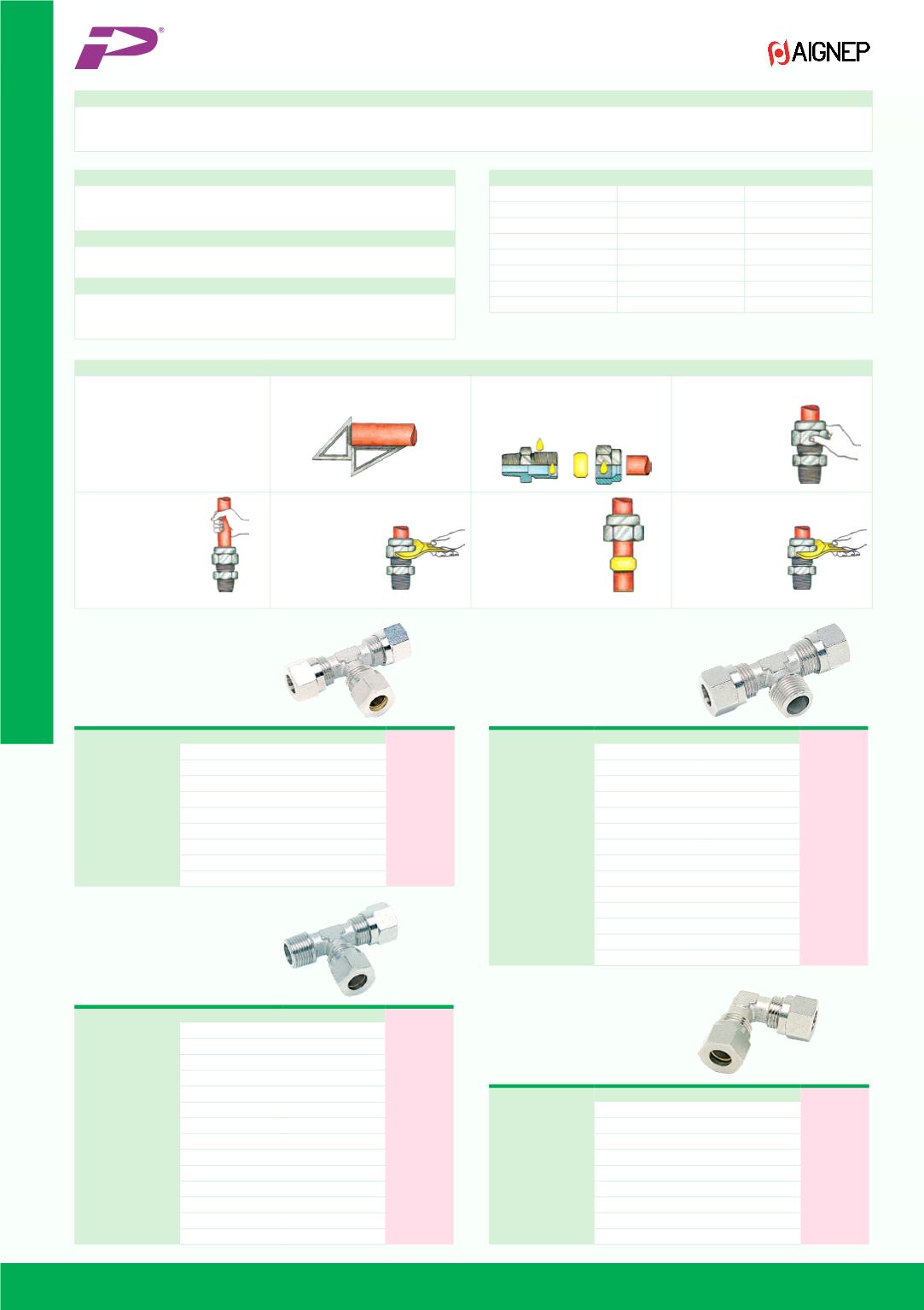

ELBOW

TUBE TO TUBE

PART NUMBER

TUBE OD

PRICE

A9260-04

4 mm

£2.58

A9260-06

6 mm

£2.83

A9260-08

8 mm

£3.32

A9260-10

10 mm

£5.31

A9260-12

12 mm

£7.07

A9260-14

14 mm

£10.93

A9260-15

15 mm

£10.93

A9260-16

16 mm

£13.51

A9260-18

18 mm

£16.32

1460

1460

1460

1460

UNIVERSAL COMPRESSION FITTINGS

SIZE

MAX. PRESSURE ADVISED

Ø 4

130 kg/cm3

128.6 bar

Ø 6

180 kg/cm3

178.1 bar

Ø 8

150 kg/cm3

148.4 bar

Ø 10

115 kg/cm3

113.8 bar

Ø 12

75 kg/cm3

74.2 bar

Ø 14

70 kg/cm3

69.3 bar

Ø 16

70 kg/cm3

69.3 bar

Ø 18

65 kg/cm3

64.3 bar

DESCRIPTION

The working pressures and working temperatures depend on which type of tube is used. For this reason, the values must be determined in accordance with the

tube’s features. The values below are the maximum pressure advised for the fittings at a temperature of 20°C connected to copper tube, which has a thickness

of 1 mm. Working pressures stated have been obtained from a test using a Safety Factor 4.

THREADS

Tapered gas in conformity with ISO 7.1, BS 21, DIN 2999.

Parallel gas in conformity with ISO 228.

Metric in conformity with ISO R/262.

FLUIDS

Water, oils, compressed air, fluids in general for the hydraulic, pneumatic &

oil dynamic plants, etc.

CONNECTION TUBES

Tubes made in copper, steel, iron, aluminium, brass, etc. With an inside

support bush, may also be used for plastic material, such as Rislan PA 11,

Nylon PA 6, etc.

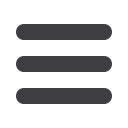

ASSEMBLY INSTRUCTIONS

To ensure the best results using

these fittings, please follow the

instructions listed.

1

. Cut the tube at 90° and remove

internal and external burrs.

2

. Lightly oil the tube nut, olive and

fitting thread. Slide the nut and olive

onto the tube, ensuring that the sharp

side of the olive is facing the fitting.

3

. Screw the nut

onto the fitting by

hand until hand-tight.

4

. Ensure that the tube is

pushed fully home

into the fitting before

tightening the nut

with the correct

spanner.

5.

Tighten nut with

the spanner one

and a quarter turns,

marking reference

points if necessary.

6

. To ensure that the

olive has gripped the

tube correctly,

unscrew the nut and

make sure that the

groove made by the

olive is even.

7. Tighten the nut again with an extra

quarter turn. When

fitting to curved

tubes, ensure that the

section entering the

fitting is straight for a

minimum length of

twice the nut height.